2026’s top construction conferences

It’s time to plan for the year to come. Construction Dive has you covered with a full list of the industry conferences and expos on tap for 2026.

https://www.constructiondive.com/news/2026s-top-construction-conferences/761559

Optimize Concrete Slab Dowel Design

How the Enhanced Integrated Dowel Model provides design recommendations for a complete set of inputs.

Because standards are intentionally conservative for most projects, but new design methods are changing, project-specific design optimization is required to provide safe, cost-effective, and sustainable construction. The newly developed Enhanced Integrated Dowel Model (EIDM) ensures joint performance under all wheel types, to reduce joint spalling and callbacks, while typically also reducing cost and improving sustainability.

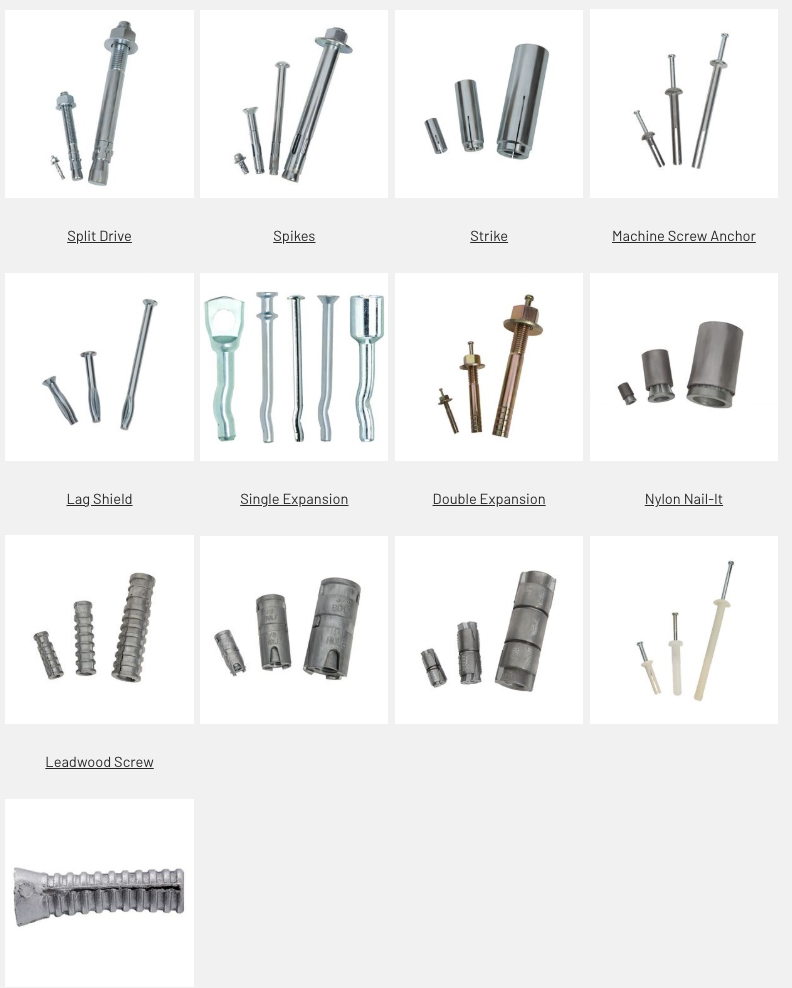

MKT American Made Sup-R Stud® + Zinc Plated Wedge Anchor

Products Features

- ZINC PLATED: Helps prevent rust in dry environments; dependable application and maintenance

- Uncracked Code Approved: ICC-ES ESR-3782 MDCPCA

- Approvals: G.S.A. Spec FF-S-325C, Group II, Type 4, Class 1

- Approvals: Miami Dade NCA No: 10-0928.01

- WIDE RANGE OF SIZES: Ensures correct fastener for effective results

- FOR USE IN CONCRETE ONLY: Provides most consistent holding values; secure application

- PACKAGED WITH NUTS AND WASHER: Fast, quick, complete installation

- HOLE SIZE IS ANCHOR SIZE: Quick and easy installation; simple to order

Say goodbye to blinding, pegging, and plugging. Livewire® from Durex Products is engineered for aggressive screening environments, combining the best of woven wire and molded rubber to boost throughput and extend wear life.

Self-Cleaning Design: Rubber strips flex with every vibration, clearing material buildup and maximizing uptime.

High Open Area, High Throughput: Lighter-gauge wire offers more open area than polyurethane for greater material flow and better performance than traditional wire.

Rugged Construction: Made from durable 60-durometer vulcanized rubber, ideal for dry or damp applications.

Versatile Wire Options: Choose XT high-tensile or stainless steel with slot styles like Accuslot™, Herringbone™, Diamond (Single/Double), and Straight.

Upgrade your screening with proven performance and longer wear life — Livewire® is the solution trusted across quarries, mines, and material handling operations.

715-483-9611

cs@durexproducts.com

www.durexproducts.com

#LivewireScreen #SelfCleaningScreens #ScreenMedia #DurexProducts #WearSolutions #MiningEquipment #AggregateProcessing #MaterialHandling #HighThroughput #EngineeredForResults #ModularScreens #HeavyDutyScreens

A little humor to share…Can you hear the OSHA?

Short video on how to install Tapcon concrete screws and more information below about installation :

Tapping Process

When tapping threads into masonry, the lead thread does all of the cutting of the masonry material and is designed to cut threads up to 1-3/4” in depth. The abrasiveness of the masonry will determine the exact depth that any specific screw can tap. The lead thread will dull and hit a point where it will no longer be able to cut threads and will stop screw penetration. As the threads are cutting into the masonry, dust is created. The threads are designed to allow the dust to be removed and to prevent interference with the screw installation. Therefore, the hole drilled in the masonry must be slightly deeper than the screw will penetrate to allow space for the dust that is created during the taping process to fall into and out of the way.

Diameter of Hole

The hole diameter is critical and must be drilled in accordance with the manufacturer’s instructions. The guidelines for masonry screw anchors are as follows: the 3/16” diameter requires the hole diameter to be equal to 5/32” and the 1/4” diameter requires a 3/16” hole. The hole must be drilled using a carbide drill bit that meets ANSI standards. ANSI standards ensure proper hole dimension tolerance requirements. Any variance in hole size will affect the holding values and may make the holding values not existent.

Making the Hole

The hole in the masonry must be drilled using an ANSI standard carbide tipped bit used in a hammer drill that is set in the hammer and rotation mode. This will ensure that the hole is the proper shape and tolerance in order to allow the screw to obtain minimum holding values. Once the hole is drilled, it must be cleaned of all dust and debris or holding values may be affected. Using a wire brush, compressed air or vacuum in combination is usually sufficient to clean out the hole before inserting the screw.

Dimensions for Self-Tapping Masonry Screws

The dimensions of all masonry screws are described with two numbers. The first number represents the diameter of the screw and the second number equals its length. They come in two diameters of 3/16” or 1/4”, with each diameter available in a number of different lengths. Each diameter comes in lengths from 1-1/4” to 6”, but not all lengths are available in both diameters. The diameter of the screw used for a specific application is determined by the holding values required and the diameter of the hole in the item being attached. The length of screw used is based on the thickness of the material being fastened. The length of the screw used for any specific application is determined by adding the minimum embedment of 1” the thickness of the material being fastened. This will give you the minimum length of screw that can be used. The maximum length of screw is determined by adding the thickness of the material being fastened to the maximum embedment of 1-3/4”.

Head Styles

Masonry screw anchors are available in two different head styles designed for different types of applications. If the application calls for the head to be countersunk in the material being fastened then the flat countersunk Phillips screw should be used. If the head of the screw will be on top of the surface of the material being fastened then the hex washer head should be used.

Types of Self-Tapping Screws

Masonry screws are manufactured from carbon steel that has a blue coating or from a 410 stainless steel which also has a protective coating. The standard blue coated masonry screw is for use in indoor applications where moisture is not present. For outdoor use or in moist atmospheres, the 410 stainless steel should be used.

American Made

The Tapcon brand is the original masonry screw and is still manufactured in the United States of America. For the best price and availability, CONFAST.com, a division of Concrete Fastening Systems, has all sizes in stock and will ship your order the same day it is placed. We also carry CONFAST brand screws, along with Simpson Strong-Tie- Visit these pages to order your prefered brand of concrete screws… online 24/7: https://www.confast.com/products-tapcon/ or https://www.confast.com/confast-concrete-screws/ or https://www.confast.com/concrete-screws/simpson-strong-tie/

Construction Nearing for University of Maine’s $170M Morse Arena

The University of Maine’s planned $170-million Athletics Facilities Master Plan takes a major step forward following the 2025 fall semester when construction starts on the new Morse Arena, a 2,660-seat basketball venue in the heart of the Orono, Maine, campus’ Athletics Village.

University officials plan to open the arena during the 2027-28 basketball season, giving fans a new home for NCAA men’s and women’s basketball while also offering Maine athletes a new sports medicine and sports performance space.

https://www.enr.com/articles/61782-construction-nearing-for-university-of-maines-new-morse-arena

Inside The World’s Largest 3D Printed Neighborhood —3D printed homes are coming to the United States. Lennar, a major home builder, partnered with the technology firm Icon to deliver 100 homes to the greater Austin, Texas area. It was an experiment that could potentially reduce production cycles and labor costs for home builders. The homes stand one story tall and are wind, fire and mold-resistant. The technique could revolutionize construction in markets that allow innovative approaches to building.