Jonas Yoder Custom Homes is showcasing an all-concrete construction approach relatively unseen before in Sarasota, Fla. The builder’s newest home in the city embraces complementary materials and techniques to make a stronger, more resilient structure than typical approaches. The all-concrete home uses Structural Concrete Insulated Panels (SCIP) from Gulf Concrete Technology of Long Beach, Miss. They meet and exceed the standards of the fortified program by the Insurance Institute for Business & Home and Safety (IBHS).https://concreteproducts.com/index.php/2024/06/27/fortified-listing/

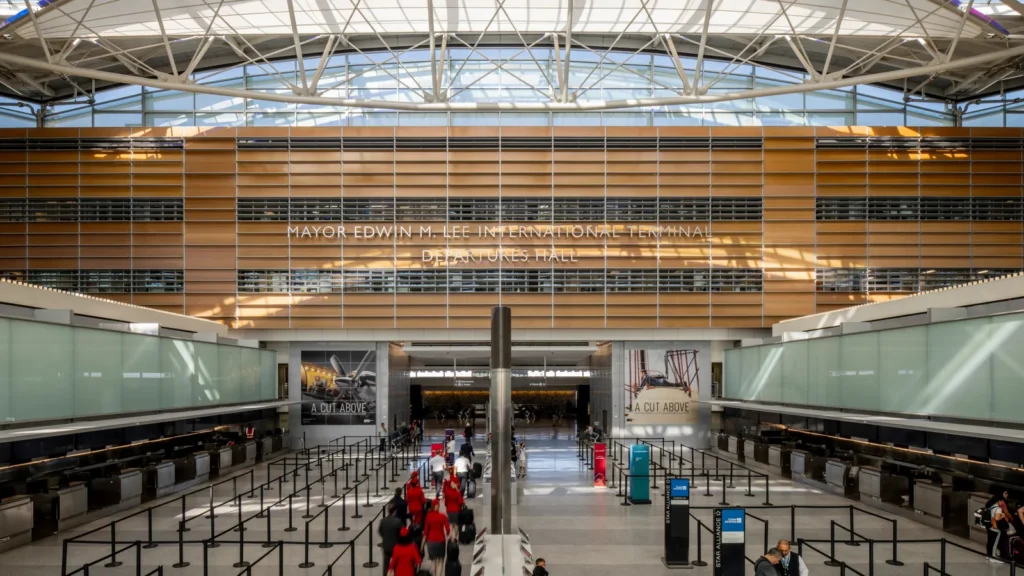

$2.9B San Francisco airport project finally takes off

After years of pandemic-related delays, the team has begun adding 200,000 square feet of additional space, security checkpoints and new passenger amenities.

https://www.constructiondive.com/news/san-francisco-airport-project-turner/725607

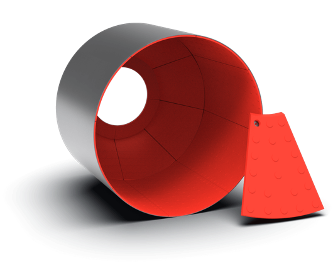

When Should Wedge Anchors be used?

Type of Base Material

Wedge anchors can only be used in solid concrete. They cannot be used in brick, block, and mortar joints. While natural base materials such as stone and granite may be solid, they are inconsistent and their holding values have not been tested. The design of the wedge anchor is such that the holding values are created at one certain point. The expansion clip requires solid contact with the base material and expands over a very short area. Attempts at using the wedge anchor in materials other than concrete will result in problems that are described below:

- The anchor will not be able to be set properly and will have no holding values.

- Once inserted into the hole, it is not possible to remove the wedge anchor.

- The wedge anchor will spin in the hole.

Concrete

Before drilling and installing a wedge anchor, the concrete must have had a minimum of 28 days to set properly. Therefore, do not install a wedge anchor into green concrete (the term describing concrete that is less than 28 days old). Installing a wedge anchor before the 28 days have passed will negatively affect the holding values.

Item Being Fastened

The item being attached affects the choice of fastener because of the variance in its thickness and weight. Also, a specific type of fastener with a certain diameter and embedment depth must be used when specified by an engineer.

- If the wedge anchor will be inserted through a hole in the item being fastened, then the hole must be larger than the diameter of the wedge anchor being installed. For example, a 1/4-inch wedge anchor requires a minimum of 5/16-inch diameter hole in the fixture.

- The surface of the item being fastened must have space allowing for a nut and washer.

- The length of the wedge anchor used is determined by the thickness of the material being fastened. Each diameter of wedge anchor is manufactured with a minimum embedment and standard length. Some diameters of wedge anchors, such as the 1/4-inch, are only available in lengths up to 3”.

Location

The wedge anchor is the only mechanical expansion anchor used in different environments that are available in four types based on plating or the steel from which it is manufactured. It is very important to select the correct type of wedge anchor to ensure that it does not rust, which would result in deteriorating holding values.

- Zinc plated –used in dry indoor environments where moisture is not present.

- Hot-Dipped-Galvanized – used where moisture is present and can be used outdoors.

- 304 Stainless Steel – used in outdoor applications, submerged in water.

- 316 Stainless Steel – used in application submerged in water with some chemicals, such as salt water or chlorine.

Overcoming Equipment Challenges for Concrete Plant Owners and Operators

Operating and owning a concrete plant can be challenging most days. However, the challenges from stone, sand, and gravel on equipment for concrete production make your day even more difficult. There are two significant challenges that can impact your bottom line. They include the high cost of steel, and noise.https://durexproducts.com/company/blog-news-events/overcoming-equipment-challenges-for-concrete-plant-owners-and-operators/

8 Questions to Rightsize Equipment for Data Center Construction

Data center construction typically includes grading, trenching, and pouring concrete. Building construction and shoring needs should be on your list, as well as safety and compliance. Does the worksite have a utility connection, or will you need generators to power everything that supports construction, from offices and cafeterias to guard shacks and parking lots? Make a list of every task that’s part of your project and then determine the machinery and accessories you need to tackle each one.

2. How Large Is Your Workforce?

Cross-reference the tasks you need to complete with the projected start date and budget to rough out a schedule. Next, consider the amount of time and manpower available for each job to determine the machines you’ll need and what each must be capable of doing.

For example, smaller pieces of equipment may not be powerful enough for heavy digging or loading or as efficient as larger machines when moving massive volumes of material. But the workforce available also makes a difference in how quickly you can finish a job.https://www.forconstructionpros.com/rental/article/22917790/sunbelt-rentals-8-questions-to-rightsize-equipment-for-data-center-construction

Humor for your day