AdventHealth taps Brasfield & Gorrie for $660M medical tower

A centerpiece of the organization’s $1 billion investment in its Orlando, Florida, campus, the building will include 24 operating rooms and 440 inpatient beds.

https://www.constructiondive.com/news/adventhealth-brasfield-gorrie-for-660m-medical-tower/749356

CONFAST Announces Availability of American-Made MKT Line of Wedge Anchors

Engineered from durable carbon steel with a zinc-plated finish, this new anchor prevents rust in dry environments, offering dependable performance and minimal maintenance. Available as Carbon Steel in Zinc Plated or Galvanized finishes, 303/304 Stainless, and 316 Stainless Steel. MKT anchors are code approved for uncracked concrete.

What do you think of this screed on big slabs? Looks like it would work but not worried about losing my job to this thing.

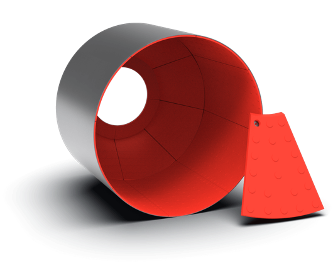

Precast Equipment Liners by Durex Products

Durex Products designs and manufactures a variety of high-performance wear parts specifically for the precast concrete industry. Our product line includes pan and planetary mixer paddles, arm guards, and scrapers engineered for compatibility with multiple mixer brands.

These components are built for durability in abrasive environments, helping to reduce downtime and extend the service life of critical equipment. Our materials and manufacturing processes ensure consistent performance and wear resistance in high-demand mixing applications. To learn more about available liner types and compatibility with your equipment, visit www.durexproducts.com

A little construction humor….

Work Smarter, Not Hotter: Temperature Regulating Gear That Keeps Crews Going

From moisture-wicking fabrics to cooling evaporative gear, temperature-regulating gear is quickly shifting from a comfort feature to a job site necessity.

Simpson Strong-Tie Titen®

The Titen Turbo screw anchor has a variety of features that make it ideal for many concrete and masonry projects. The innovative Torque Reduction Channel traps drilling dust to prevent it from obstructing thread action. The reverse thread design is patented and enables smooth driving with less torque while providing superior holding power. The Torque Reduction Channel also allows more space for dust to help prevent anchors from bottoming out in smaller-diameter screw holes. In addition, the Titen Turbo screw anchors feature a serrated leading edge to cut into concrete or masonry, and a pointed tip for fast, easy installation in wood-to-concrete and wood-to-wood anchoring applications. Buy today: https://www.confast.com/concrete-screws/simpson-strong-tie/simpson-strong-tie-titen/

Since things are a little crazy right now thought we would add a little more humor to this month’s post.